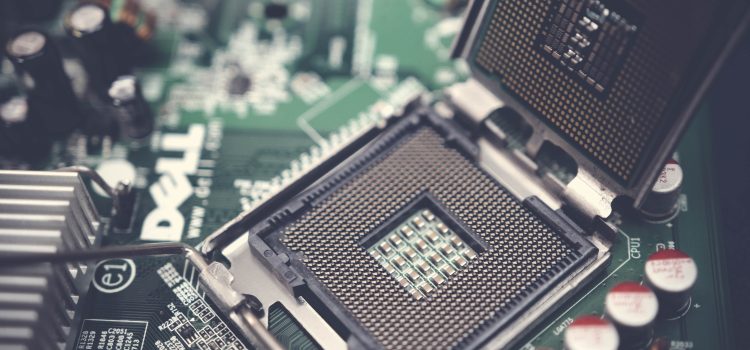

The global chip shortage has been a hot topic in the tech industry over the past year. As demand for electronics continues to rise, the supply of semiconductors and microchips has failed to keep up. This has led to delays in production and supply chain disruptions for a variety of electronic devices, including smartphones, laptops, and even cars. The shortage has hit the US electronics industry particularly hard, as the country relies heavily on semiconductor imports and is home to many of the world’s leading tech companies.

One of the main reasons for the chip shortage is the COVID-19 pandemic, which caused many chip factories to shut down or reduce their output. At the same time, the pandemic has led to a surge in demand for electronics as people work, learn, and entertain themselves from home. This has created a perfect storm of supply and demand imbalances, which has resulted in a shortage of chips.

The US electronics industry has been hit hard by the chip shortage, with companies such as Apple, Microsoft, and Intel all reporting delays in production and shortages of components. The shortage has also affected the automotive industry, with car manufacturers such as Ford and General Motors having to reduce production due to a lack of semiconductors.

To address the shortage, the US government has taken several steps to increase domestic chip production. In June 2021, the Senate passed the US Innovation and Competition Act, which includes $52 billion in funding for the semiconductor industry. This funding will be used to increase domestic chip production and improve the supply chain for critical electronic components.

Many US electronics companies are also looking for alternative sources of chips to mitigate the impact of the shortage. Some companies are exploring the use of older, less sophisticated chips in their products, while others are turning to suppliers in other countries, such as Taiwan and South Korea.

The chip shortage has also highlighted the importance of diversifying supply chains and reducing reliance on a single country or region for critical components. This is especially true for the US, which relies heavily on imports of semiconductors and microchips from Asia.

In conclusion, the global chip shortage has had a significant impact on the US electronics industry, causing delays in production and supply chain disruptions. However, the crisis has also spurred innovation and investment in domestic chip production and supply chain resilience. The lessons learned from the shortage will be crucial for the industry to adapt and thrive in the future.