In the age of climate crisis, every industry is called upon to reassess its practices and adopt sustainable solutions. One crucial sector under scrutiny is packaging. Long criticized for its contribution to environmental degradation, packaging is undergoing a transformation aimed at reducing carbon footprints and increasing renewability. This article delves into the innovative strategies employed in the packaging industry to achieve these goals, exploring how these advancements are cutting carbon emissions and fostering a more sustainable future.

The Evolution of Sustainable Packaging

Historically, packaging has been synonymous with excess waste and pollution. However, as awareness of environmental issues grows, so too does the demand for eco-friendly alternatives. The evolution of sustainable packaging encompasses various approaches, including material innovation, design optimization, and end-of-life solutions.

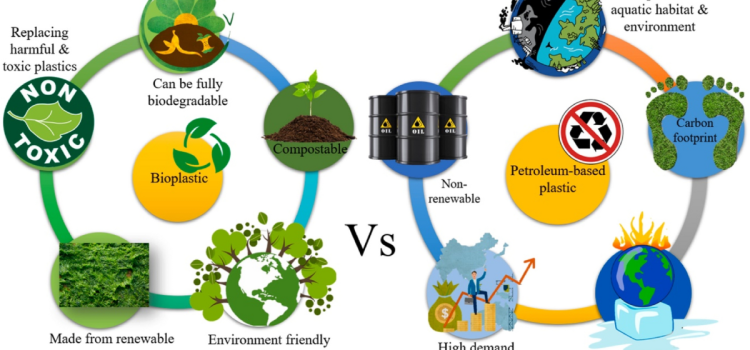

Material Innovation: From Plastic to Biodegradables

One of the most significant shifts in packaging is the move away from traditional plastics toward biodegradable and renewable materials. Plant-based polymers derived from sources such as corn starch, sugarcane, and cellulose offer a viable alternative to petroleum-based plastics. These materials not only reduce reliance on finite fossil fuels but also decompose more readily, lessening environmental impact.

Design Optimization for Efficiency

In addition to material innovation, optimizing packaging design plays a crucial role in reducing carbon emissions. Streamlining packaging dimensions and utilizing lightweight materials decrease transportation costs and energy consumption throughout the supply chain. Furthermore, innovative designs, such as collapsible or stackable packaging, minimize wasted space, leading to fewer shipments and lower emissions.

End-of-Life Solutions: Embracing Circular Economy Principles

The concept of a circular economy, wherein resources are reused and recycled rather than disposed of, is gaining traction in the packaging industry. Closed-loop systems facilitate the recovery and repurposing of packaging materials, mitigating waste and reducing the need for virgin resources. Initiatives such as extended producer responsibility (EPR) programs encourage manufacturers to take responsibility for the disposal and recycling of their products, incentivizing the adoption of more sustainable packaging practices.

Analyzing Carbon Reduction

To assess the efficacy of these sustainable packaging initiatives in cutting carbon emissions, a comparative analysis is imperative. The table below outlines the carbon footprint of traditional packaging materials versus their sustainable counterparts:

| Packaging Material | Carbon Footprint (kg CO2 equivalent per ton) |

|---|---|

| Traditional Plastics | 1,600 |

| Biodegradable Plastics | 900 |

| Plant-based Polymers | 600 |

| Recycled Paper | 400 |

| Cardboard | 350 |

Comparative Impact: Carbon vs. Renewability

While reducing carbon emissions is paramount, it is equally essential to consider the renewability of packaging materials. The table below compares the carbon footprint and renewability of various packaging options:

| Packaging Material | Carbon Footprint (kg CO2 equivalent per ton) | Renewability |

|---|---|---|

| Traditional Plastics | 1,600 | Low |

| Biodegradable Plastics | 900 | Medium |

| Plant-based Polymers | 600 | High |

| Recycled Paper | 400 | High |

| Cardboard | 350 | High |

Conclusion

The packaging industry’s transition toward sustainability marks a significant step in the fight against climate change. Through material innovation, design optimization, and a commitment to circular economy principles, packaging manufacturers are not only cutting carbon emissions but also enhancing renewability. As increasingly prioritize eco-conscious products, the demand for sustainable packaging will continue to drive innovation, ultimately fostering a more environmentally responsible future.