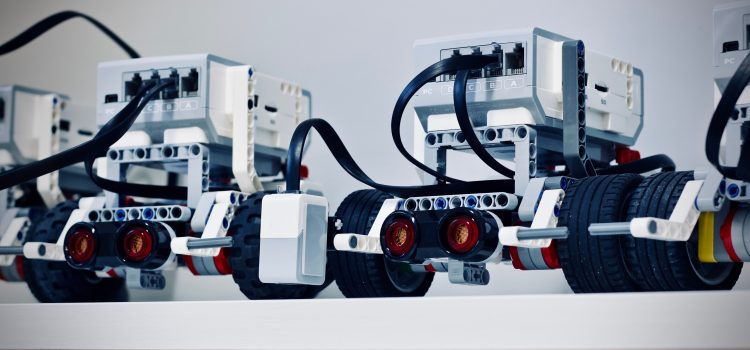

As technology advances at an unprecedented pace, robotics and automation are rapidly transforming the manufacturing industry. The use of robots in manufacturing processes has increased efficiency, reduced costs, and improved quality control. However, this shift has also led to concerns about job displacement and the need for upskilling in the workforce.

According to a report by the International Federation of Robotics, there were over 2.7 million industrial robots operating in factories worldwide in 2019. By 2022, this number is expected to increase to 3.9 million. This growth is due in part to advancements in artificial intelligence, which allow robots to learn and adapt to new tasks.

One industry that has seen significant changes due to robotics and automation is the automotive industry. Car manufacturers use robots to assemble parts, paint cars, and perform quality control checks. This has led to faster production times, higher quality standards, and reduced costs.

The healthcare industry is also experiencing a shift towards automation. Robots are being used to assist with surgeries, dispense medication, and provide patient care. This trend is expected to continue as the aging population creates a greater demand for healthcare services.

However, as with any technological shift, there are concerns about job displacement. While robots may increase efficiency, they also require fewer human workers. The solution to this issue lies in upskilling the workforce to handle more complex tasks that robots cannot yet perform. This requires a commitment to lifelong learning and a willingness to adapt to new technologies.

Despite these concerns, the benefits of robotics and automation in manufacturing and other industries cannot be ignored. As we move into the future, it is likely that we will see an increasing number of robots and automated systems in our daily lives. It is up to us to prepare for these changes and find ways to integrate them into our society in a way that benefits everyone.