Introduction to 3D Printing

3D printing, also known as additive manufacturing, has evolved rapidly from a theoretical concept in the 1980s to a practical and widely used technology today. At its core, 3D printing involves creating a three-dimensional object by layering material based on a digital model, allowing for intricate and complex designs that were once impossible with traditional manufacturing methods.

This revolutionary process is changing the landscape of industries from healthcare to automotive, aerospace to architecture, and more. Instead of subtracting material from a larger piece as in traditional manufacturing (known as subtractive manufacturing), 3D printing adds material layer by layer, resulting in less waste and more efficient use of resources. As this technology advances, it is becoming faster, more versatile, and accessible, unlocking endless possibilities for innovation.

Innovations in 3D Printing

The innovation in 3D printing has accelerated in recent years, with advancements in materials, speed, and precision making the technology more capable and diverse. Below are some of the most groundbreaking innovations that are shaping the future of 3D printing:

Faster Printing Times

One of the most significant challenges in 3D printing has been the relatively slow production time for creating objects. Early 3D printers could take hours or even days to print a single item, depending on the size and complexity. However, modern breakthroughs are significantly improving printing speeds, making it a more efficient option for mass production.

High-Speed Sintering (HSS):

This technique utilizes infrared light to heat a powder bed, allowing for faster sintering (or bonding of the material). It has the potential to print in 10 times less time compared to conventional 3D printing methods, particularly when it comes to producing complex geometries and functional parts.

Continuous Liquid Interface Production (CLIP):

Developed by Carbon3D, CLIP is one of the most significant advancements in 3D printing. It utilizes light and oxygen to cure a photosensitive resin, continuously printing layers without pauses. This enables the creation of fully formed objects in a matter of minutes, compared to traditional 3D printing, which can take hours or days. CLIP has already been used to produce everything from consumer products to medical devices.

Benefits: These innovations reduce lead times for production, increase throughput, and make 3D printing more feasible for industries that require fast turnaround times, such as automotive and healthcare.

Multimaterial and Multicolor Printing

In the past, 3D printers were limited to printing with a single material at a time, typically plastic. Today, the evolution of multimaterial printing allows the integration of multiple materials in a single object, each with specific properties suited to different parts of the design.

- Stratasys and HP have pioneered multimaterial 3D printing that can combine flexible, rigid, transparent, and opaque materials in one print, making it possible to create functional parts that require different mechanical properties in different sections.

Example: In the automotive industry, Ford has used multimaterial 3D printing to create complex dashboard components that require both soft and hard materials in a single piece, enhancing comfort and functionality. Similarly, in medical applications, multimaterial prosthetics are becoming more common, allowing for better comfort and more precise fits.

Benefits: This innovation opens up new possibilities for creating more intricate and functional parts, particularly in sectors like aerospace, automotive, and healthcare, where parts need different properties (e.g., flexibility, strength, heat resistance).

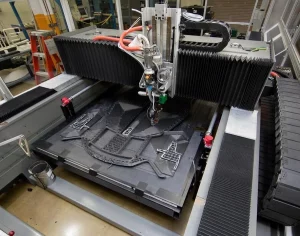

3D Printing with Metal and Composite Materials

While plastic has been the most common material used in 3D printing, the advent of metal and composite 3D printing has been a game-changer, especially in industries that demand high-strength, durable materials.

- Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) are two techniques that enable 3D printing of metal parts. These methods use lasers to fuse metal powder into solid parts with precise detail and strength. Aerospace companies, such as NASA and Boeing, use metal 3D printing to create lightweight yet durable parts that would be challenging or impossible to manufacture using traditional methods.

- Composite materials, such as carbon fiber-infused plastics, are also gaining traction in 3D printing. These materials combine the strength of fibers with the flexibility of plastics, making them ideal for high-performance applications like automotive and aerospace.

Case Study: NASA has 3D printed key parts for space exploration using metal and composite materials, including fuel components and structural pieces for spacecraft. The technology allows NASA to create parts in space using local resources, reducing dependency on Earth-based supply chains.

Benefits: Metal and composite 3D printing is especially useful in industries like aerospace, automotive, and defense, where high-performance parts are essential. The ability to produce parts with complex geometries and superior mechanical properties at lower costs is a huge advantage.

Bioprinting: The Future of Healthcare

One of the most exciting frontiers in 3D printing is bioprinting, where living cells are used to print tissues and organs. This groundbreaking technology could eventually enable the creation of transplantable organs, which would address the global shortage of donor organs.

- Bioprinting involves using bioinks, which are specialized materials composed of living cells and biomaterials like collagen or gelatin. The printer deposits the bioinks layer by layer to create tissue-like structures, which can potentially be used for transplants, drug testing, and medical research.

Case Study: In 2023, researchers at the University of Bristol successfully printed functional human heart tissue, a major milestone in the field. While scientists are still years away from printing full organs like hearts or kidneys, this research represents a step closer to personalized medicine and organ regeneration.

Benefits: Bioprinting could revolutionize organ transplantation, reducing waitlists and increasing the availability of organs. It also holds the promise of customized treatments and implants tailored to individual patients, improving outcomes in complex medical procedures.

Sustainable 3D Printing with Recycled Materials

Sustainability is a growing concern in manufacturing, and 3D printing offers an eco-friendly alternative to traditional production methods. With innovations in recycled materials, 3D printing can help address environmental challenges by reducing waste and promoting recycling.

- Filabot, a company specializing in 3D printing, allows users to recycle plastic waste and turn it into usable filament for 3D printing. This not only helps reduce the amount of plastic waste in landfills but also lowers the carbon footprint associated with producing new plastic filaments.

- Recycled materials like PETG and ABS, commonly used in 3D printing, are now being produced with recycled content. In addition, biodegradable materials, such as PLA (polylactic acid), are also gaining popularity due to their reduced environmental impact.

Benefits: Recycled 3D printing materials help reduce waste and promote the circular economy. This aligns with global sustainability goals, especially in industries that generate significant amounts of plastic waste.

Applications of 3D Printing Across Industries

3D printing is not just a manufacturing tool; it’s a transformative technology with wide-ranging applications across industries. Let’s explore how it’s being applied in various sectors:

1. Healthcare and Medicine

In healthcare, 3D printing is enabling customization and personalization like never before. From prosthetics to surgical models, the technology is improving patient outcomes and reducing costs.

- Custom Prosthetics: Traditional prosthetics often require long waiting times and are not always a perfect fit for the patient. With 3D printing, prosthetics can be tailored to an individual’s specific body dimensions, improving comfort and functionality. The technology has been used to produce prosthetic limbs that are lighter, more affordable, and better fitting than traditional options.

- Surgical Planning and Practice: Surgeons can now use 3D-printed models of patients’ organs or tumors for pre-surgical planning. This allows them to practice complex surgeries before operating on the patient, improving accuracy and reducing the risk of complications.

- Bioprinting: 3D printing human tissue and organs is still in its infancy, but it holds enormous potential. In the future, we could see 3D-printed skin grafts, cartilage, and even heart valves used for medical treatments, reducing the need for organ transplants.

Case Study: Materialise has been printing customized surgical guides for joint replacements and even printing bone models for pre-surgery planning. This approach has led to faster recovery times and better outcomes for patients.

Aerospace and Aviation

Aerospace is another industry where 3D printing is gaining a foothold, particularly for producing lightweight components and parts with complex geometries.

- Boeing, NASA, and Airbus are some of the key players in adopting 3D printing to produce parts for aircraft and spacecraft. By printing lightweight engine components and structural elements, they can reduce the overall weight of their products, leading to fuel savings and improved efficiency.

- Parts with Complex Geometries: Traditional manufacturing methods struggle to produce certain complex geometries, but 3D printing excels in this area. Aerospace manufacturers can now

3D Printing: Innovations and Applications

Automotive Industry

The automotive industry has long been a pioneer in utilizing new technologies to enhance vehicle design, safety, and manufacturing processes. 3D printing has made its mark here, allowing automakers to reduce development times, lower production costs, and produce more innovative designs.

- Prototyping and Custom Parts: Traditionally, car manufacturers would spend weeks or even months designing and testing prototypes. With 3D printing, parts can be rapidly prototyped in just hours or days, allowing designers to test fit and function early in the design process. This ability to print custom car parts on-demand has drastically reduced the lead times for prototype development.

- Lightweight Components: Automakers are also leveraging 3D printing to manufacture lightweight car components. Parts such as brackets, housings, and bumpers are being printed with metal alloys and composite materials, which make them stronger while reducing the overall weight of the vehicle. Lighter vehicles consume less fuel and produce fewer emissions, making them more eco-friendly.

Example: BMW has been using 3D printing for many years to produce parts for its vehicles, including the i8 hybrid sports car. The company has even created custom-fit car parts for specific customer needs, like seat inserts and door panels, tailored for comfort and performance.

Benefits: With 3D printing, automotive manufacturers can streamline their design and prototyping processes, reduce waste, and create parts that improve the vehicle’s performance and sustainability.

Fashion and Design

Fashion designers are increasingly adopting 3D printing to produce customized fashion pieces and innovative accessories. This application of 3D printing is helping designers push the boundaries of traditional fashion design, creating intricate, one-of-a-kind pieces that are impossible to produce using conventional methods.

- Custom Clothing and Jewelry: 3D printing allows for the creation of bespoke clothing and jewelry tailored to an individual’s measurements. Designers can create unique patterns and structures, enabling greater creativity and personalization in the fashion industry.

- Textiles and Footwear: 3D-printed footwear is one of the most exciting innovations in fashion. Companies like Adidas have teamed up with 3D printing manufacturers to create custom-fit shoes. The Futurecraft 4D project, for example, uses 3D printing to create customized midsoles designed to offer optimal performance based on the wearer’s walking or running style.

Case Study: Iris van Herpen, a leading fashion designer, is known for her avant-garde use of 3D printing to create unique dresses and accessories. Her designs push the limits of textile manufacturing by incorporating geometric and organic forms that would be impossible to achieve through traditional techniques.

Benefits: 3D printing allows fashion designers to reduce waste, create unique, customizable products, and experiment with new materials and designs, offering a more sustainable and creative approach to fashion.

Construction and Architecture

The construction industry is undergoing a massive transformation with the introduction of 3D printing, particularly in the form of 3D-printed buildings and construction materials. These innovations have the potential to disrupt traditional building methods and provide solutions to issues such as housing shortages, sustainability, and speed of construction.

- 3D-Printed Homes: Companies like ICON and Apis Cor are using large-scale 3D printers to create homes using concrete, composite materials, and other sustainable resources. These homes can be printed in a matter of days, at a fraction of the cost of traditional construction methods.

- Sustainability and Affordability: 3D-printed homes can be built with minimal material waste, reducing the environmental impact of construction. Additionally, because 3D printing eliminates many labor-intensive tasks, these homes can be made more affordable for low-income families.

Case Study: ICON, in partnership with New Story, has created the world’s first 3D-printed neighborhood in Mexico. The neighborhood consists of several homes built with an automated 3D printer, and it is a significant step toward addressing global housing crises with affordable, sustainable housing solutions.

Benefits: The use of 3D printing in construction is helping to make housing more affordable, increase efficiency, and reduce waste. It also allows for greater design flexibility, enabling architects to create complex structures with minimal materials.

The Future of 3D Printing

The future of 3D printing is incredibly exciting, with numerous advancements on the horizon. As we look toward the next decade, here are some of the key areas in which 3D printing is expected to evolve:

1. Advancements in Speed and Precision

Currently, one of the biggest limitations of 3D printing is the speed at which it can produce large volumes of products. However, with the development of new technologies like CLIP, multi-laser systems, and high-speed sintering, we can expect significantly faster printing speeds in the near future. These advancements will allow 3D printing to compete with traditional manufacturing methods for mass production.

Moreover, increased precision and resolution will enable the creation of more intricate designs with tighter tolerances, enhancing the functionality of printed objects.

2. Artificial Intelligence and Automation Integration

Artificial intelligence (AI) will play a crucial role in the future of 3D printing. With AI, 3D printers could optimize designs in real-time, detect potential errors during the printing process, and ensure that the final product meets the highest standards of quality.

Example: AI-enabled 3D printers could analyze data from past prints to predict potential failures or imperfections in the design, automatically adjusting the printing parameters to prevent issues before they arise.

3. Expanding Material Options

One of the most promising areas of growth in 3D printing is the development of new materials. Beyond the traditional plastics and metals, researchers are working on advanced composites, biodegradable plastics, and even edible materials for use in industries like food production and pharmaceuticals.

- Bioprinting is also on the rise, with the potential to print human tissues and organs, paving the way for a future where patients could receive personalized organs made just for them.

4. 3D Printing in Space Exploration

One of the most intriguing potential applications of 3D printing is in space exploration. NASA and other space agencies are researching ways to use 3D printing to create tools, spare parts, and even habitats for astronauts on long-term missions to the Moon, Mars, and beyond.

The ability to print parts and equipment in space reduces the need to launch everything from Earth, saving costs and weight. It also allows for the creation of customized equipment and spare parts on-demand, ensuring that astronauts have the tools they need, no matter the situation.

Challenges in 3D Printing

Despite its tremendous potential, 3D printing faces several challenges that need to be addressed in order to unlock its full potential:

1. Material Limitations

While the range of materials available for 3D printing is growing, it is still somewhat limited compared to traditional manufacturing. There are challenges in printing with certain materials, such as metals, composites, and biomaterials, which require specialized printers and techniques.

2. High Initial Investment Costs

The cost of high-quality 3D printers and materials remains a barrier for many businesses, particularly small enterprises. While the cost of 3D printers has come down over the years, professional-grade machines capable of printing in advanced materials can still be quite expensive.

3. Standardization and Regulation

As 3D printing becomes more integrated into industries like healthcare and aerospace, it is essential to establish clear standards and regulations to ensure the quality, safety, and reliability of printed parts. This is particularly important in fields like medical implants and aerospace components, where failure can have severe consequences.

Conclusion

3D printing has moved beyond the realm of prototyping and experimentation to become a fundamental part of modern manufacturing, healthcare, fashion, construction, and more. The ongoing innovations in speed, material science, and applications are continually expanding the capabilities of this technology, making it one of the most exciting fields in today’s technological landscape.

As 3D printing continues to evolve, it promises to revolutionize the way we produce and consume products, leading to more sustainable, personalized, and efficient solutions. From customized medical implants to entire 3D-printed neighborhoods, the possibilities are vast, and the future of 3D printing is poised to transform industries in profound ways.

While challenges like material limitations and high equipment costs remain, the trajectory of 3D printing suggests that it will play a pivotal role in shaping the future of manufacturing and beyond, driving innovation and opening up new frontiers in a range of industries.