In recent years, the advent of 3D printing technology has brought about transformative changes in various industries, and the field of prosthetics is no exception. This innovative technology is revolutionizing the way prosthetic limbs are designed, manufactured, and fitted, offering unprecedented levels of customization, affordability, and accessibility. Here, we explore how 3D printing is reshaping the landscape of prosthetics, providing new hope and improved quality of life for individuals with limb loss.

Customization and Personalization

One of the most significant advantages of 3D printing in prosthetics is the ability to create highly customized devices tailored to the specific needs of each patient. Traditional prosthetic limbs often require multiple fittings and adjustments, a process that can be time-consuming and costly. In contrast, 3D printing allows for the precise scanning of a patient’s residual limb, creating a digital model that can be adjusted to ensure a perfect fit.

This level of customization extends beyond just the fit of the prosthetic. Patients can choose the color, design, and even add personal touches to their prosthetic limbs, making them a more integral and personalized part of their lives. This not only enhances the functional aspects of the prosthetic but also has a positive impact on the psychological well-being of the wearer.

Affordability and Accessibility

Cost has always been a significant barrier in the field of prosthetics, with traditional prosthetic limbs often costing thousands of dollars. 3D printing is dramatically lowering these costs, making prosthetic limbs more accessible to a broader range of individuals. The materials used in 3D printing are generally less expensive than those used in conventional manufacturing, and the production process is more efficient, reducing labor costs.

Moreover, 3D printing technology is becoming increasingly accessible around the world. Non-profit organizations and startups are leveraging this technology to provide affordable prosthetic solutions to individuals in developing countries, where access to traditional prosthetics is often limited. This democratization of prosthetic technology is empowering individuals and communities, enabling them to overcome physical limitations and improve their quality of life.

Speed and Efficiency

The traditional process of creating a prosthetic limb can take several weeks or even months, involving multiple stages of casting, molding, and fitting. In contrast, 3D printing can significantly expedite this process. Once a digital model is created, a 3D printer can produce a prosthetic limb in a matter of hours. This rapid production capability is particularly beneficial in situations where time is of the essence, such as providing prosthetics to victims of natural disasters or conflict zones.

The speed and efficiency of 3D printing also allow for quicker iterations and improvements. If a prosthetic limb needs adjustments or modifications, these can be made swiftly and cost-effectively, ensuring that patients receive the most functional and comfortable devices possible.

Innovation and Advancements

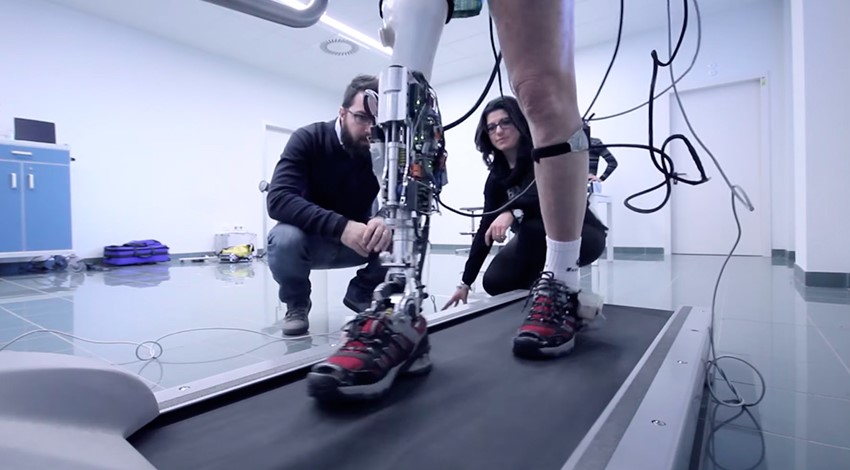

3D printing technology is continuously evolving, leading to exciting advancements in the field of prosthetics. Researchers and engineers are exploring new materials, such as lightweight and durable composites, that can enhance the performance and longevity of prosthetic limbs. Additionally, the integration of smart technologies, such as sensors and actuators, is paving the way for more advanced prosthetic devices that can mimic natural limb movements and provide real-time feedback to the user.

One notable development is the creation of bionic limbs that incorporate 3D-printed components. These high-tech prosthetics can be controlled by the user’s muscle signals or even brainwaves, offering a level of functionality that was once the realm of science fiction. Such innovations are not only improving the physical capabilities of prosthetic limbs but also opening up new possibilities for rehabilitation and therapy.

Collaborative Efforts and Future Prospects

The revolution in prosthetics driven by 3D printing is a collaborative effort involving various stakeholders, including researchers, healthcare professionals, engineers, and patients. This multidisciplinary approach is fostering a culture of innovation and continuous improvement, ensuring that the latest advancements are translated into practical solutions that benefit users.

Looking ahead, the future of 3D-printed prosthetics is incredibly promising. As technology continues to advance, we can expect to see even more sophisticated and functional prosthetic devices that are tailored to the unique needs of each individual. The integration of artificial intelligence and machine learning could further enhance the capabilities of prosthetic limbs, enabling them to adapt and respond to the user’s movements and environment in real-time.

Furthermore, the ongoing development of biocompatible materials and tissue engineering holds the potential to create prosthetic limbs that are not only functional but also seamlessly integrated with the body. This could lead to a new era of prosthetics that are indistinguishable from natural limbs in terms of appearance and performance.

Conclusion

3D printing is undeniably revolutionizing the field of prosthetics, offering a range of benefits that were previously unimaginable. From enhanced customization and affordability to rapid production and continuous innovation, this technology is transforming the lives of individuals with limb loss, providing them with new opportunities and improved quality of life. As we continue to push the boundaries of what is possible with 3D printing, the future of prosthetics looks brighter than ever, promising a world where everyone has access to the best possible prosthetic solutions.